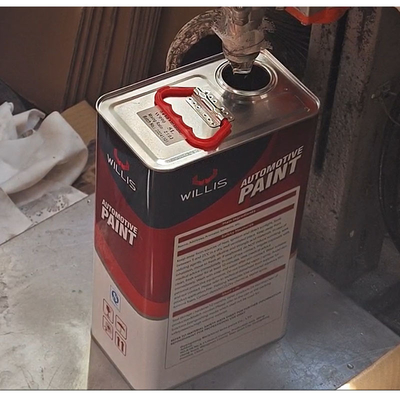

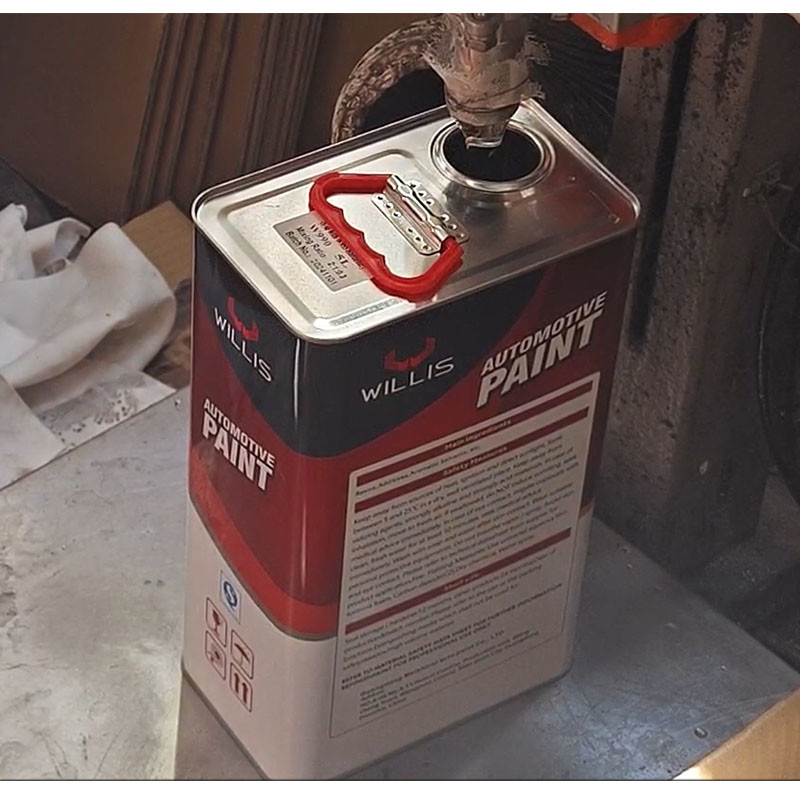

ODM Automotive Clear Coat Paint Ultrafast Dry Thinner Hardener Grit Sandpaper

Product Details:

| Place of Origin: | China,Guagndong |

| Brand Name: | Willis brand |

| Model Number: | A-940/A-5500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | ≥18 Liters |

|---|---|

| Price: | $0.99-$6.99,Negotiation |

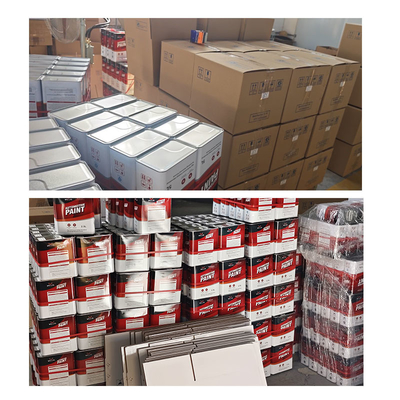

| Packaging Details: | 0.5L*24,1L*12,4L*6,5L*6. The package will be customized. |

| Delivery Time: | 6-15days |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 24000 Cartons Monthly production |

|

Detail Information |

|||

| Brand Name: | FantasyColor, Shangfu, Mt Yishili | Other Names: | Varnish |

|---|---|---|---|

| Color: | Transparent | Service: | OEM/ODM |

| Mixing Ratio: | Clear Coat:hardener=2:1:0.3-0.5 | Package: | According To Client's Request |

| Function: | Scratch Repair/Partial Repair/Full Vehicle Renovation/Full Vehicle Color Change/Customized Finished Paint | Shelf Life: | 5 Years, Two Year Before Being Opened, 2 Years In Original Container At 20°C, Cool And Dry Place At 25℃, 2 Years In Original Sealed Can |

| Highlight: | ODM Automotive Clear Coat Paint,45pm Automotive Clear Coat Paint |

||

Product Description

Automotive paint protection coating automotive clear coat paint/ultrafast dry (thinner,hardener ) Grit Sandpaper

![]()

Product features:

1. high solid content, high film thickness, high gloss, high hardness

2. Good weather resistance, no color change, no light loss

3. Convenient construction and excellent chemical resistance

4. Thickness 35-45pm

Surface preparation:

1. Surface Should be clean and free of dust, grease and oil.

2. Old varnish surfaces must be sanded using grit sandpaper number 1200, before applying the clear coat.

Application:

Anti-rust, anti-rust paint/ship/automotive paint metal paint/automotive curing agent/automotive varnish/paint/industrial paint/advertising marking paint

Product description:

| TYPE | A two-pack, polyurethane finish enamel based on Acrylic Polyol, resins and non-yellowing Isocyanate Hardener with weather resistant pigments. | |||

| USES | Top coat for vehicles, bridges, boot top, topside steel structures, and wooden and metal products, etc. | |||

| CHARACTERISTICS | 1. High gloss with excellent appearance. 2. Excellent resistance to weathering with gloss retention. 3. Excellent resistance to oils, acids, alkalis and solvents. 4. Excellent hardness, adhesion and abrasion resistance. | |||

| GLOSS | Above 90% | |||

| COLOR | Desired colors | |||

| WEIGHT | Above 1.0 kg/L (Mixer) | |||

| VISCOSITY (25 °C) | 60– 85 KU (Mixer)(25 °C) | |||

| DRYING TIME (25 °C) | Set-to-touch 1 hr. Dry hard 6 hrs. (25 °C). | |||

| OPTIMUM FILM THICKNESS | Wet 95μ(microns)Dry 30μ(microns) | |||

| MIXER RATIO | Base: Hardener = 2: 1 (by volume.) | |||

| NON-VOLATILE CONTENT | Above 50% | |||

| POT LIFE | 4 hrs. (Mixture , 25 °C) | |||

| THINNER | PU Thinner | |||

| THINNING RATE | 10~25 % | |||

| STORAGE SHELF LIFE | Minimum 1 year under normal storage conditions. | |||

| APPLICATION METHOD | Spray, Brush. | |||

| NOTES | 1. Mix base and hardener according to the mixing ratio and stir thoroughly. 2. Avoid applying the paint in rain or humid weather, particularly, awet surface must be thoroughly dried. 3. All equipments must be cleaned immediately after use. 4. When used inside tanks, sufficient ventilation must be provided. 5. When overcoating interval is exceeded, paint surface must be roughened to insure adhesion. 6. Hardener can must be tightly closed to avoid reaction with moisture in air toform bubbles and gelation. 7. Strictly controlling application, not be exceed 60μ pre coat, to avoid bubbles for mation. |

|||

Mixing ratio: clear coat:hardener=2:1:0.3-0.5

| Drying Time | Temperature | DUST FREE | TACK FREE | COMPLETE DRY |

| 20℃ | 1h | 2-3 hours | 24h | |

| 60℃ | 5 minutes | 10 minutes | 60 minutes |

Construction technology:

1. Clean&Shade

Remove wax oil and other impuritieswith deoiling detergent Examine andassess the location and extent of damage.

2. Grind damaged parts

Grinding with abrasive paper(#80# 2000). Dry grinding withsandpaper(#80, 120, 180) first.

3. Dust cleaning

Use a degreaser to remove greasefrom the workpiece.

4. Fill& Grind

Add thne hardener I proportionmix and fill the putty, Sanding(#80. 120, 180) after drying.

5. Clean &Grind

Clean the surface again, and thenfinely grind the filling to the leveof the paint.

6. Spray primer surfacer

Mix and spray primer according toproduct requirements, each layerneeds to be matte.

7.Grind primer surfacer

After the primer is dried, dry sandingpaper(3320-400)is used with atwo-way sander. Manual grindingon the edge(#600-800)

8. Clean & Wipe

Use a cleaner to clean the grease.and tack cloth to clear of dustand particles.

9. Spray 1K color paint

Add thinner as requiredspray2-3ayers, spray interval of 5-10nutes per layer.

10. Spray Varnish(clear coat)

Add hardener and thinner asrequired, spray two layerseach interval is 5-10 minutes.

11. Dry Bake

After the varnish is sprayed. it needbe allowed to stand for 10-15minutes can be baked or driednatur.

12. Waxing &Polish

Can be sanded with abrasivepaper(#2000)first if necessaryThen use related products forwaxing and polishing

Saft Precautions :

1. Keep container in a well ventilated and cool place

2. Keep away from fire

3. Avoid contact with eye and skin

4. Wear suitable gloves and eyes protection

5. Don't empty into drains

6. Against static discharges